This past spring, Daniel Knapp headed out from our office to McMaster University to make a presentation to the Canadian simulation community on the results of a study on the cost effectiveness of exhaust air heat recovery technologies. The study was carried out using CAN-QUEST in thirteen different building types and in all six Canadian climate zones. The study examined the costs and benefits of adding various heat recovery technologies to a wide range of system types and sizes. The linked study shares a number of details on how the cost benefit analysis was carried out and how different heat recovery technologies were found to perform in each building type, but for this post we thought it would be helpful to focus on a few key design strategies that allow heat recovery to perform to its highest potential.

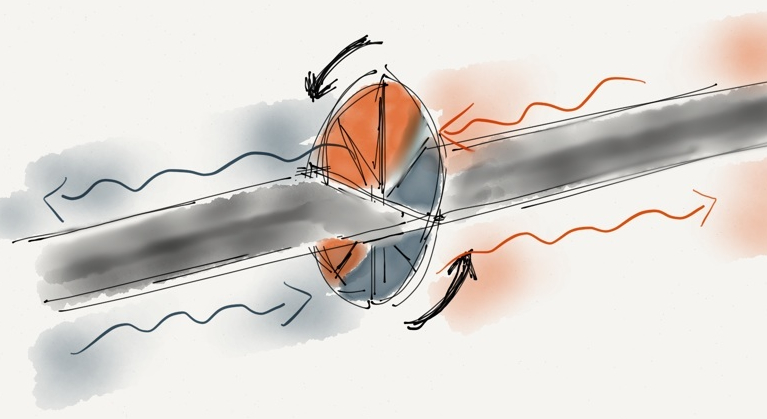

Heat recovery works by recovering heat from the exhaust air stream and transferring this heat to the incoming outdoor air stream (during the summer heat can be moved from the outdoor air stream to the exhaust air stream, reducing the cooling load). A heat recovery system with 100% effectiveness would be able to raise the incoming outdoor air temperature to the indoor air temperature and completely eliminate the outdoor air heating load. As conditioning of outdoor air represents a significant fraction of the heating and cooling loads for a building, the use of heat recovery can greatly reduce energy consumption and associated greenhouse gas emissions. The results of our study indicate that heat recovery is cost effective with short payback periods in most building types including offices, schools, retail, multi-unit residential buildings, hotels, health-care, etc. We also found that a number of strategies are useful to consider in designing heating, ventilating, and air-conditioning (HVAC) systems to maximize the benefit of heat recovery systems and increase energy savings. These strategies are listed below:

- heat recovery works best in systems with outdoor air fractions above 20%. Right-sizing the system will ensure that the supply air flow rate will be as low as possible, and will increase the outdoor air ratio. Even better, designing an HVAC system around a dedicated outdoor air system with 100% outdoor air will lead to significant energy savings

- designing for higher supply air temperatures in winter, ideally above 21ºC, allows the heat recovery system to recover more useful heat from the exhaust air

- traditional variable-air-volume (VAV) systems represent a challenging system design for heat recovery as they tend to supply cool air (13 to 15ºC) to zone terminals which provide most of the heat. They also tend to be designed with low outdoor air fractions. Right-sizing the system to reduce the supply air flow rate will increase the outdoor air fraction. Using a supply air temperature reset strategy which raises the supply air temperature during periods of peak heating loads will allow the HVAC system to move more of the heating load to the central system where more heat can be recovered from the exhaust air

- the importance of including controls to allow the outdoor air to bypass the heat recovery system cannot be understated. There are times, especially in fall and winter, when it is desirable to bring in outdoor air without heating it to provide ‘free cooling’. Using heat recovery under these conditions would overheat the supply air and cause unnecessary activation of the cooling coil. Without bypass control heat recovery can increase the energy consumption of a building in warmer climate zones

- a number of different technologies were reviewed in our study. Of these technologies we found that energy wheels provided excellent value as they tend to provide high performance at a relatively low cost with excellent bypass control.